Feed size: 125-1200 mm

Output: 1-1000 t/h

Application range: widely used in the crushing of marble, limestone, limestone, granite, shale, and other stones.

Product description:

The jaw crusher is called "the tiger's mouth". It is a crusher that consists of two jaw plates, a movable jaw, and a static jaw, that forms a crushing cavity, which simulates the movement of the two jaws of an animal to complete the material crushing operation.

The working principle of jaw stone crusherequipment

The motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate closer to the fixed jaw plate, and the material is crushed or split at the same time. When the movable jaw descends, the angle between the toggle plate and the movable jaw becomes smaller. The movable jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring. At this time, the crushed materials are discharged from the lower mouth of the crushing chamber. . With the continuous rotation of the motor, the crushing motor jaw makes the periodic movement to crush and discharge materials, realizing mass production.

Features of jaw crusherfor sale

1. The parts are made of highly wear-resistant materials, and the parts have a long service life.

2. Gasket-type discharge opening adjustment device, with a large adjustment range.

3. The equipment is not easy to be damaged, and the operating cost is economical.

4. Large crushing ratio and uniform product size

5. Energy saving and environmental protection, the jaw crusher has low noise and pollution during use.

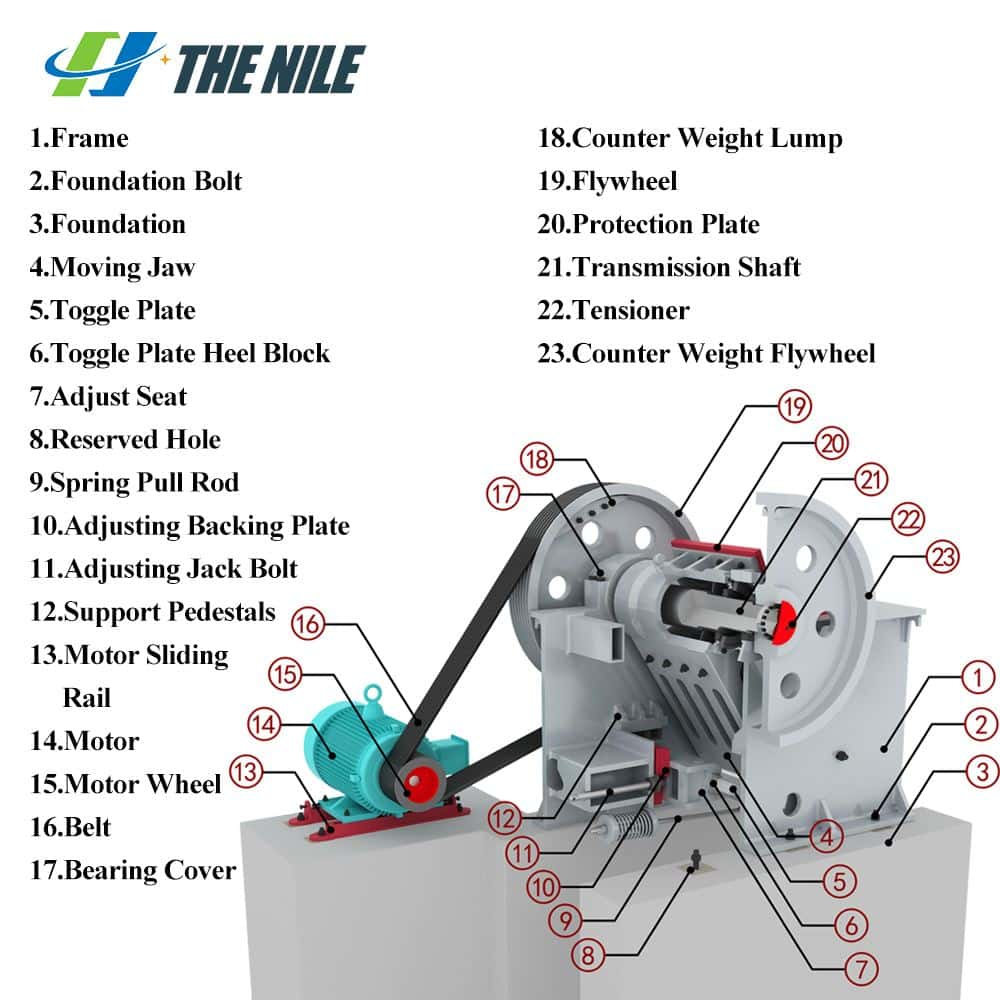

The structure of the jaw crushing machine

Jaw crusher equipment is mainly composed of frame, movable cone, fixed cone, toggle plate, flywheel, eccentric shaft, large pulley, and so on.

Packaging and shipping

Company strength

Company strength

The Nile Machinery Equipment Co., Ltd. is a metallurgical machinery professional machinery factory that specializes in mining equipment research and development, manufacturing, sales, and provides professional mining processing plant workflow design, plant installation, equipment maintenance, and mineral processing technical guidance services. Our products are exported to Africa, Nigeria, Zambia, Zimbabwe, Uganda, Mozambique, South America, the Middle East, and many other countries and regions. At present, we have established our own overseas warehouses in Sudan and Kenya, and we also have our offices in most parts of Africa. You can observe the machinery up close and buy directly, saving transportation costs and time.

customer visit

Project cases

Project: 150 T sand and gravel aggregate production line

Material: Bluestone

Output: 150T

Equipment configuration: PE750*1060 jaw crusher, one PF1315 impact crusher, and one 2YK2460 vibrating screen.

Detailed description: A mine owner from Africa contacted the Nile River for a configuration list of 150 tons of bluestone crushing production line per hour. After understanding the situation, our technicians conducted a detailed investigation and understanding of the location of the customer’s production site, the weather conditions, and the specific conditions of the stone. Although the output is not high, we strive to make it better and design more reasonable bluestone. The final result of the sand-making production line program is very satisfying to customers.

| Model | Max. Feeding size | Discharge size | Capacity | Motor power | Weight | Dimension |

| (mm) | (mm) | (t/h) | (kW) | (t) | (mm) | |

| PE150*250 | 125 | 10-40 | 1-3 | 5.5 | 0.7 | 1000*870*990 |

| PE250*400 | 210 | 20-60 | 5-20 | 15 | 2.8 | 1300*1090*1270 |

| PE400*600 | 340 | 40-100 | 16-60 | 30 | 7 | 1730*1730*1630 |

| PE400*900 | 340 | 40-100 | 40-110 | 55 | 7.5 | 1905*2030*1658 |

| PE500*750 | 425 | 50-100 | 40-110 | 55 | 12 | 1980*2080*1870 |

| PE600*900 | 500 | 65-160 | 50-180 | 75 | 17 | 2190*2206*2300 |

| PE750*1060 | 630 | 80-140 | 110-320 | 90 | 31 | 2660*2430*2800 |

| PE900*1200 | 750 | 95-165 | 220-450 | 160 | 52 | 3380*2870*3330 |

| PE1000*1200 | 850 | 195-265 | 315-500 | 160 | 55 | 3480*2876*3330 |

| PEx150*750 | 120 | 18-48 | 8-25 | 15 | 3.8 | 1200*1530*1060 |

| PEx250*750 | 210 | 15-60 | 13-35 | 30 | 6.5 | 1380*1750*1540 |

| PEx250*1000 | 210 | 15-60 | 16-52 | 37 | 7 | 1560*1950*1390 |

| PEx250*1200 | 210 | 15-60 | 20-61 | 45 | 9.7 | 2140*2096*1500 |

| PEx300*1300 | 250 | 20-90 | 16-105 | 55 | 15.6 | 2720*2210*1600 |