The PE series jaw crusher is a commonly used rough crushing equipment. It is mainly used to crush various medium-hard ores and rocks with a compressive strength of not more than 350 MPa. It has a large crushing ratio, high output, uniform product size, reliable work, and easy maintenance, low operating cost, and other advantages. The maximum processing capacity can reach 1000 t/h, and the work efficiency is high.

Product description

PE series jaw crushing machine is widely used for coarse crushing of various ores and rocks. It is a commonly used crushing equipment in mines. The PE series jaw crusher has 11 models, and the maximum processing capacity can reach 1000 t/h. It has many advantages such as high work efficiency, a large crushing ratio, uniform product size, and a wide application range. It can meet the production needs of various large and medium-sized enterprises.

Working principle

The PE series jaw stone crusher is powered by an electric motor and drives the eccentric shaft through a belt drive to make the movable jaw move back and forth according to a predetermined trajectory, so as to enter the crushing cavity composed of a fixed jaw plate, a movable jaw plate, and a side guard plate. The materials are crushed, and the finished materials are discharged through the lower discharge port. The motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate to approach the fixed jaw plate, and at the same time, the material is squeezed, Multiple crushing such as splitting and bending; when the movable jaw descends, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring. At this time, the crushed materials are discharged from the lower opening of the crushing chamber. With the continuous rotation of the motor, the crusher jaw makes periodic crushing and discharge to realize mass production.

Features of jaw crusher machine for sale:

1. Gasket-type discharge opening adjustment device, flexible and convenient, with a large adjustment range.

2. The tooth plate adopts high wear-resistant parts, which have a long service life and the equipment is not easy to be damaged.

3. Large crushing ratio, uniform product size, and low pollution.

4. Fully automatic control system, convenient and quick.

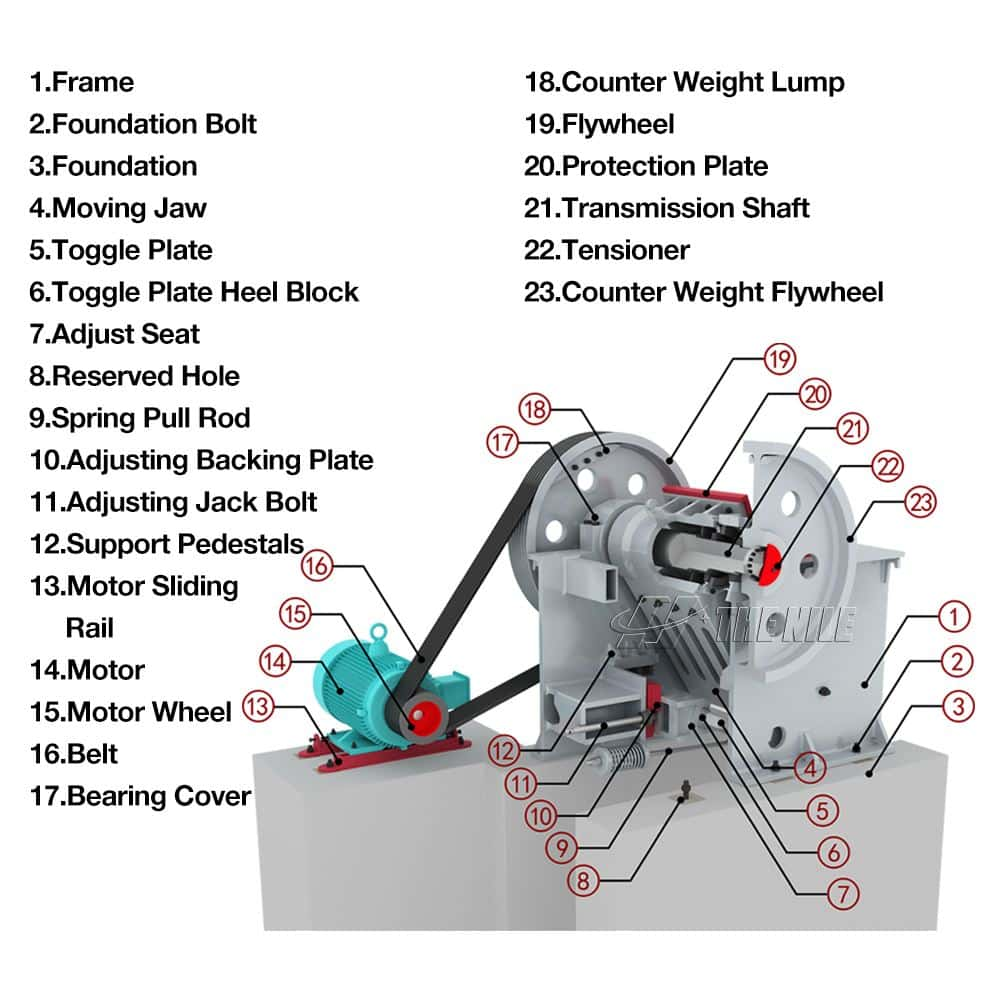

The structure of the stone jaw crusher machinery:

The PE series jaw rock crusher equipment is mainly composed of a frame, an eccentric shaft, a large pulley, a flywheel, a fixed jaw plate, a movable jaw, a side guard plate, a toggle plate, a toggle plate rear seat, and a movable jaw plate.

Jaw stone crusher production process:

Company strength

The Nile Machinery Co., Ltd. is committed to designing various types of equipment such as stone crushing equipment, mineral ore beneficiation equipment, gold beneficiation equipment, and sand-making equipment. The products are exported to all parts of the world, especially in Europe, America, and Africa, and are well received by customers.

Packaging and shipping

The jaw crusher equipment produced by the Nile manufacturer is not only of good quality but also at a price far lower than the market price. Products can be transported to all parts of the world, and overseas warehouses in Kenya and Sudan can be directly picked up. We use fully enclosed container packaging during the entire transportation process, with a low product damage rate and fast transportation.

Project cases:

Project: 150 T sand and gravel aggregate production line

Material: Bluestone

Output: 150T

Equipment configuration: PE750*1060 jaw crusher, one PF1315 impact crusher, and one 2YK2460 vibrating screen.

Detailed description: A mine owner from Africa contacted the Nile for a configuration list of 150 tons per hour bluestone crushing production lines. After understanding the situation, our technicians conducted a detailed investigation and understanding of the location of the customer’s production site, the weather conditions, and the specific conditions of the stone. Although the output is not high, we strive to make it better and design more reasonable bluestone. The final result of the sand-making production line program is very satisfying to customers.

| Model | Max. Feeding size | Discharge size | Capacity | Motor power | Weight | Dimension |

| (mm) | (mm) | (t/h) | (kW) | (t) | (mm) | |

| Pe150*250 | 125 | 10-40 | 1-3 | 5.5 | 0.7 | 1000*870*990 |

| Pe250*400 | 210 | 20-60 | 5-20 | 15 | 2.8 | 1300*1090*1270 |

| Pe400*600 | 340 | 40-100 | 16-60 | 30 | 7 | 1730*1730*1630 |

| Pe400*900 | 340 | 40-100 | 40-110 | 55 | 7.5 | 1905*2030*1658 |

| Pe500*750 | 425 | 50-100 | 40-110 | 55 | 12 | 1980*2080*1870 |

| Pe600*900 | 500 | 65-160 | 50-180 | 75 | 17 | 2190*2206*2300 |

| Pe750*1060 | 630 | 80-140 | 110-320 | 90 | 31 | 2660*2430*2800 |

| Pe900*1200 | 750 | 95-165 | 220-450 | 160 | 52 | 3380*2870*3330 |

| Pe1000*1200 | 850 | 195-265 | 315-500 | 160 | 55 | 3480*2876*3330 |

| Pex150*750 | 120 | 18-48 | 8-25 | 15 | 3.8 | 1200*1530*1060 |

| Pex250*750 | 210 | 15-60 | 13-35 | 30 | 6.5 | 1380*1750*1540 |

| Pex250*1000 | 210 | 15-60 | 16-52 | 37 | 7 | 1560*1950*1390 |

| Pex250*1200 | 210 | 15-60 | 20-61 | 45 | 9.7 | 2140*2096*1500 |

| Pex300*1300 | 250 | 20-90 | 16-105 | 55 | 15.6 | 2720*2210*1600 |