News

Home > News > Industry News

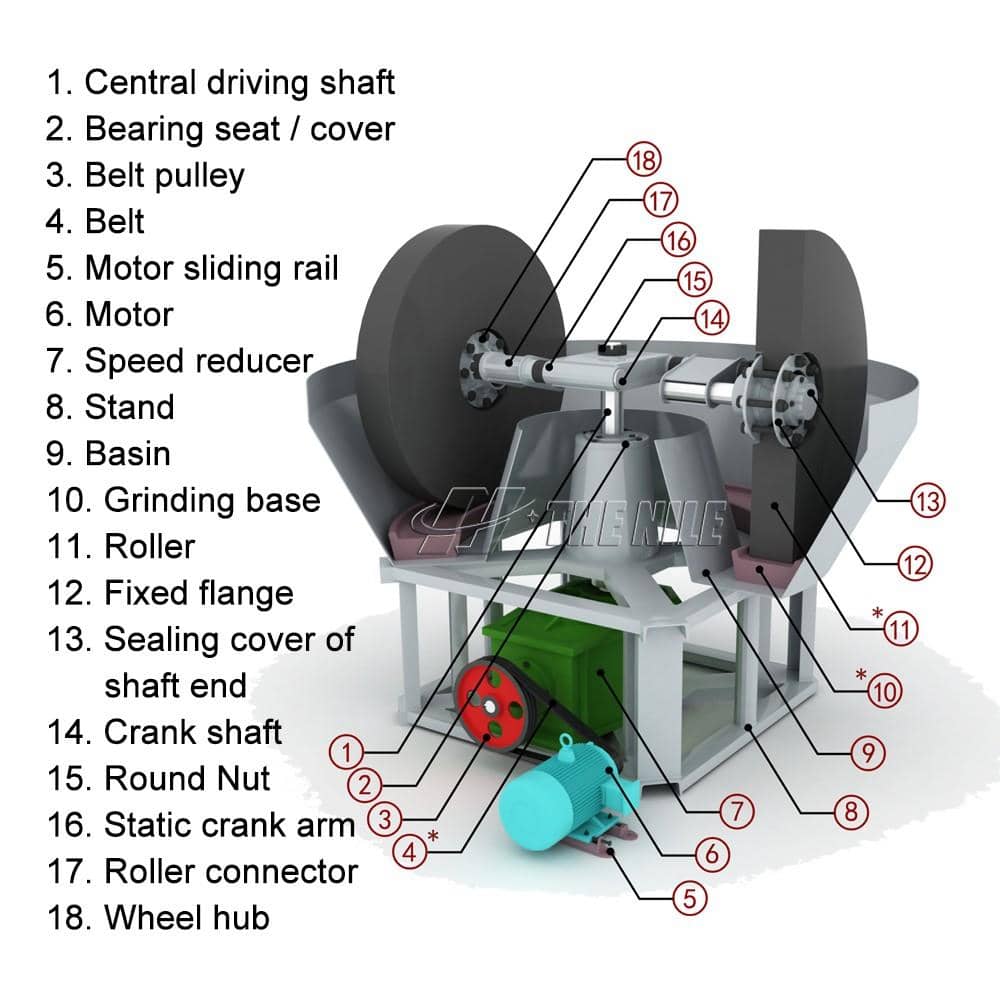

The Wet Pan Mill is also called Wet Grinding Machine. Based on the different structure it is divided into double roller grinding and three roller grinding. They are mainly used for grinding operations, such as all kinds of ferrous metal, non-ferrous metal, non-metallic minerals, and the separation of gold, silver, lead, iron, copper and so on.

Working principle:

The wet pan mill works under the wheel grinding system:

Firstly reduction box would be driven by the motor, then under the drive of reduction box, the torque is transmitted to the upper cross axle through the large vertical shaft and then to the runner wheels through the straining beams installed on both ends of the cross axle. The runner wheels are driven to rotate anti-clockwise along the horizontal direction of the cross axle. When the runner wheels are working, they could not only revolve around the large vertical shaft of the wet pan mill but also revolve their own axles. The grinding base stays fixed at the same time. The added mineral materials are thoroughly crushed and ground under the force of the runner wheels’ body weight, the huge friction force between the runner wheels and grinding base which is produced by the runner wheels’ revolution and auto-rotation, as well as the repeated squeeze, curating and grinding.

The wet pan mill mainly consists of the power plant, body frame, water basin, grinding roller, and grinding base.

The Wet Pan Mill is always used in small and medium scale grinding system for rock gold because of its lower cost.

The mercury could be added into the mill when grinding the gold ore so as to catch the released gold.