News

Home > News > Industry News

Grinding ball mill is a kind of machine that wildly used in mineral production. The raw material is ground from coarse to a fine powder and then ultra-fine powder.

And these kinds of equipment are especially handy for the ground of wet material and lightweight material. It can ignore the influence of the mineral's specific gravity, and both wet and dry material can be well treated. The finished product can satisfy the ultra-fine powder standard (the smallest up to 1250 mesh).

Working principle of Energy-saving Ball Mill :

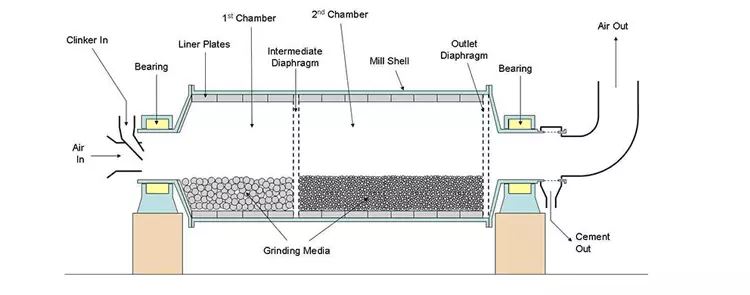

The grinding ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Structure of Energy-saving Ball Mill :

The grinding ball mill is composed of the feeding part, discharging part, turning part and driving part (reducer, small driving gear, electric motor, and electric control). The quill shaft adopts the cast steel part and the liner is detachable. The turning gearwheel adopts casting hobbing process and the drum is equipped with wear-resistant liner, which has good wear-resistance. The ultrafine ball mill is with stable and reliable working condition.

Product Site:

Grind ball mill participation in engineering case:

Gravity Beneficiation Line For Gold Ore