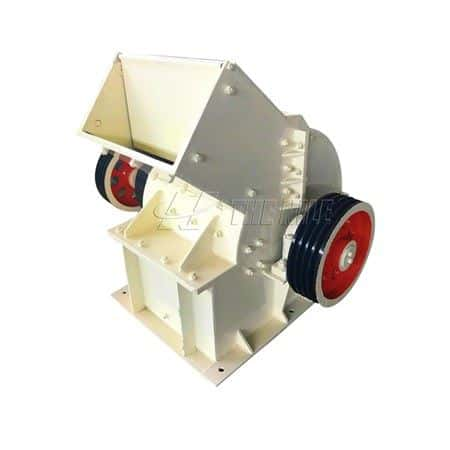

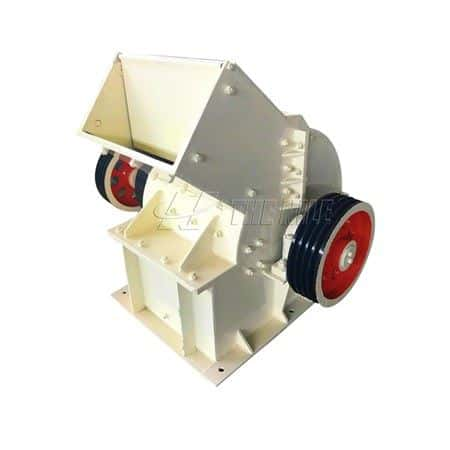

Processing Materials: Energy saving hammer crusher is mainly used to crush coal for power plants, but it can also be used for crushing gypsum, salt chemical raw materials, and some medium-hard materials. It is a kind of crusher that can directly crush the materials with the maximum particle size of 600-1800 mm to 25 or less.

Working Principle of Energy Saving Hammer Crusher

Energy-saving Hammer crusher is composed of box, hammerhead, rotor, sieve plate, impact lining plate, etc. It mainly depends on the impact of energy to complete the crushing operation. When working, the motor drives the rotor to rotate at a high speed, and the materials enter the crusher cavity evenly. The high-speed rotating hammer impacts, cuts, and tears the material, which causes the material to be crushed. At the same time, the gravity of the material itself makes the material rush from the high-speed rotating hammerhead to the baffle plate and screen bar in the frame. At the lower part of the rotor, there is a sieve plate, and the particle size of the crushed material is smaller than the mesh size. After discharging through the sieve plate, the material larger than the mesh size will stay on the sieve plate and continue to be hit and ground by the hammer until it is crushed to the required discharge particle size, and finally discharged out of the hammer crusher through the sieve plate.

Performance Characteristics of Energy Saving Hammer Crusher

1.The working hammer of the energy-saving hammer crusher is cast with a new process, which is wear-resistant and impact-resistant.

2.The required particle size can be adjusted according to customer requirements.

3.Compact structure, beautiful appearance, good wear resistance, and convenient maintenance.

4.The overall design has the advantages of beautiful appearance, compact structure, less vulnerable parts, convenient maintenance, etc., which is an upgraded energy saving hammer crusher.

5. The structure of the energy-saving hammer crusher body is sealed, which solves the problem of dust pollution and dust leakage of the machine body in the crushing workshop.

Technical Parameters of Energy Saving Hammer Crusher

Model No. | Max. Feeding Size | Output Size | Capacity | Motor Power | Weight | Overall Diemension |

PC400*300 | 100 | ≤10 | 5-10 | 11 | 0.8 | 850*950* 880 |

PC600*400 | 120 | ≤15 | 10-25 | 18.5 | 1.5 | 1000*1000*1300 |

PC800*600 | 120 | ≤15 | 20-35 | 55 | 3.1 | 1515*2590*1040 |

PC1000*800 | 120 | ≤15 | 20-40 | 110 | 7.9 | 3200*2210*1515 |

PC1000*1000 | 120 | ≤15 | 30-80 | 132 | 8.65 | 3515*2230* 1515 |