Products

Home > Products > Mineral Processing Equipment > Gravity Separation Plant

Processing Materials: Gold gravity separation process is mainly used for the gravity beneficiation of tungsten ore, tin ore, manganese ore, mercury ore, titanium ore, lead ore, tantalum niobium ore, barite, fluorite, pyrite, limonite, hematite, antimony ore, chromite, and other minerals, as well as metal recovery from various metal smelting slag.

Application of Gold Gravity Separation Process

Gold gravity separation process is suitable for processing ores or other raw materials with a large density difference between useful minerals and gangue. The gold gravity separation process is an effective method for processing coarse, medium, and fine ores (the approximate boundaries are larger than 25 mm, 25 "2 mm, 2 ~ 0.1 mm).

Performance Characteristics of Gold Gravity Separation Process

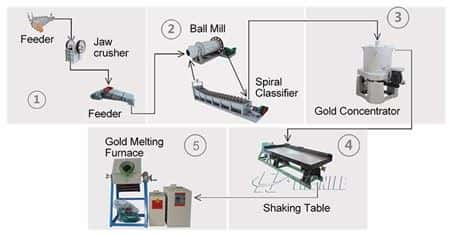

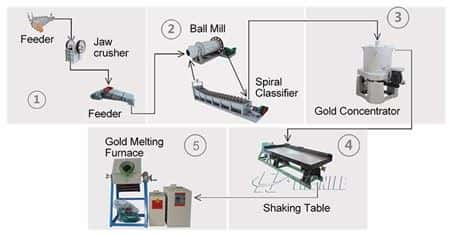

Gold gravity separation process is a process in which the appropriate separation conditions and loose stratification are formed with the help of fluid power and various mechanical forces according to the different mineral density or particles, so as to obtain products of different densities or particle size. Gold gravity separation process can be divided into heavy medium separation, jig separation, shaking table separation, spiral chute separation, centrifugal concentrator separation, etc. Our professional beneficiation design engineers will design a reasonable production process and recommend appropriate gravity separation equipment according to the actual situation of the ore and the user's separation requirements.