Disc filter is an indispensable device on the transmission medium pipeline. It is usually installed at the inlet end of a pressure-reducing valve, pressure relief valve, constant water level valve, or other equipment to eliminate impurities in the medium and protect the normal use of valves and equipment.

Product description:

The disc filter is designed to optimize the overall performance and the comparability of the components to ensure that the metal minerals are dense, fast settling, and the filtrate containing solid particles have a strong impact on the filtrate tube. Obtain an excellent dehydration index during separation.

Working principle of disc filter machine

The disc vacuum filter is composed of a disc of each individual fan-shaped piece. Each fan-shaped sheet is a separate filter unit, which is made of filter cloth and covered on the fan-shaped sheet to form a filter chamber. The filter disk is driven by a motor through a reducer and an open gear drive. The filter disk rotates clockwise. The slurry in the filter chamber is attached to the filter disk by the pressure difference formed by the vacuum pump on both sides of the filter medium in the adsorption zone. After the cake is caked, the agitator rotates to prevent solid precipitation. After the filter cake leaves the liquid surface, the water is continuously removed under the action of a vacuum. The filtrate passes through the filter cloth, passes through the filtrate pipe, and is discharged from the dispensing head. The filter cake is discharged into the discharge trough by the reverse blower in the discharge area, and the whole operation process is continuously carried out in a continuous cycle.

Features of disc filter equipment

1. The filter cloth of the disc filter has an automatic cleaning device to maintain a good dehydration effect.

2. Each disc of the disc vacuum filter machine is composed of multiple fan-shaped plates, which strengthens the control of the filtering process and makes the cake thickness uniform.

3. The wear-resistant nylon, single or multifilament filter cloth is used to make the cake removal rate high and not easy to be blocked, and the service life is long.

4. The fan-shaped filter plate of the disc filter equipment has a uniform distribution of dewatering holes, a reasonable porosity, and a large rib size.

5. The filter plate and the filtrate tube are made of high-strength, high wear-resistant materials, and have a long service life.

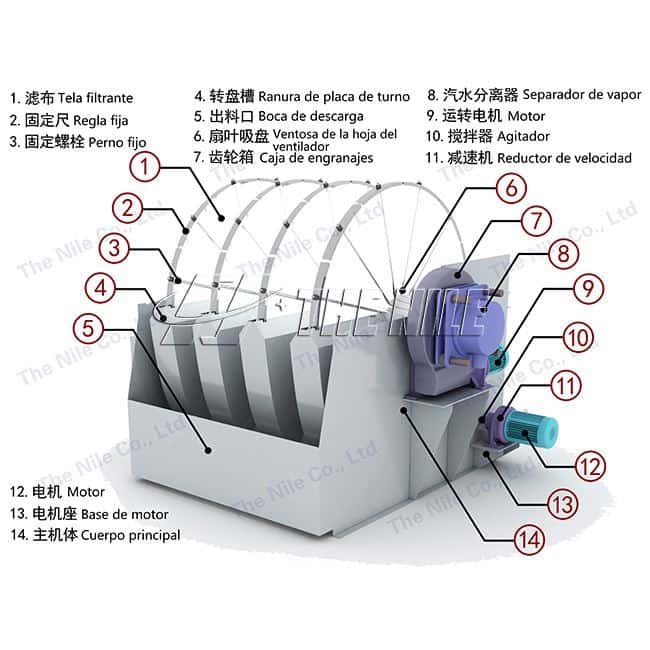

The structure of the disc filter for sale

The disc filter machine is mainly composed of filter fan, main shaft, filter tube, distribution valve, stripping device, flushing device, net washing device, transmission device, and discharging device.

Company strength

The Nile Machinery Equipment Co., Ltd. is a metallurgical machinery professional machinery factory that specializes in mining equipment research and development, manufacturing, sales, and provides professional mining processing plant workflow design, plant installation, equipment maintenance, and mineral processing technical guidance services. Our products are exported to Africa, Nigeria, Zambia, Zimbabwe, Uganda, Mozambique, South America, the Middle East, and many other countries and regions. At present, we have established our own overseas warehouses in Sudan and Kenya, and we also have our offices in most parts of Africa. You can observe the machinery up close and buy directly, saving transportation costs and time.

customer visit

No more→

| Model | ZPG-15 | ZPG-20 | ZPG-30 | ZPG-40 | ZPG-60 | ZPG-72 | ZPG-96 | ZPG-120 | |

| Filtering area(m²) | 15 | 20 | 30 | 40 | 60 | 72 | 96 | 120 | |

| Filtering plate | Diameter(mm) | 2100 | 2100 | 2100 | 3100 | 3100 | 3100 | 3100 | |

| Quantity (pcs) | 6 | 6 | 6 | 6 | 6 | 6 | 8 | 10 | |

| Spindle motor power(kw) | 2.2 | 3 | 3 | 4 | 5.5 | 5.5 | 7.5 | 11 | |

| Stirring motor power(kw) | 3 | 3 | 4 | 5.5 | 7.5 | 7.5 | 11 | 15 | |

| Weight (t) | 9 | 11 | 12.5 | 14 | 19.3 | 20.3 | 23 | 25.5 | |

| Capacity (t/h) | 10-15 | 15-20 | 22-30 | 30-40 | 45-70 | 50-90 | 60-120 | 80-150 |