A multi-cylinder cone rock crusher is typical crushing equipment for medium and fine crushing of hard materials. It is developed on the basis of the spring cone crusher, and its basic structure is similar to the spring cone crusher.

Product description

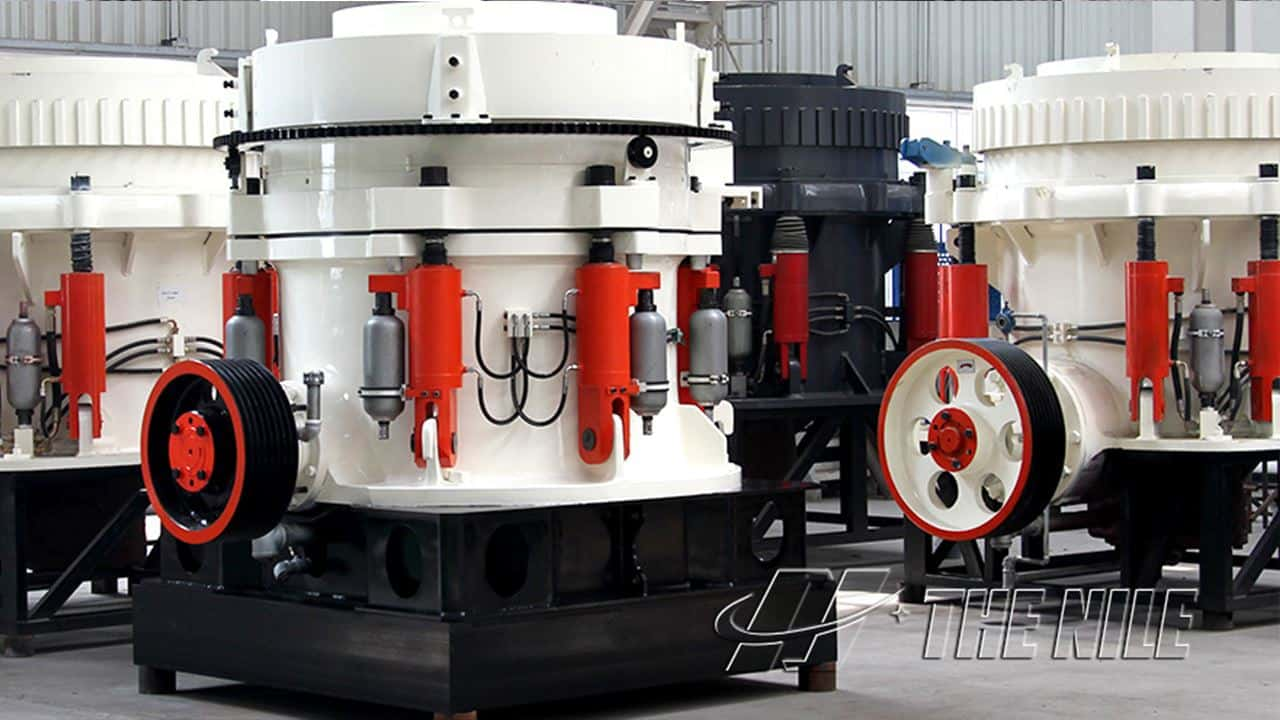

A multi-cylinder cone rock crusher is typical crushing equipment for medium crushing and fine crushing of hard materials. It integrates high swing frequency, optimized cavity shape, and reasonable stroke to meet the diverse needs of users. Multi-cylinder hydraulic cone crushers are widely used in mining, construction, electric power, metallurgy, transportation, and other industries.

Working principle of multi-cylinder hydraulic cone crusher machine

When the multi-cylinder hydraulic cone crusher is working, the moving cone rotates along the inner surface. Near the fixed cone, the material is crushed by the squeezing and bending of the moving cone. Where it deviates from the moving cone, the crushed material is due to gravity. The action drops from the bottom of the cone, and the entire crushing and unloading process proceeds continuously along the inner surface.

Features of multi-cylinder hydraulic cone rock crusher

1. The equipment has a long service life. The frame and main shaft of the multi-cylinder hydraulic cone crusher are made of high-strength alloy steel precision casting and precision forging, which are durable and suitable for crushing medium-hard materials.

2. Large eccentricity moment, good grain shape. The multi-cylinder hydraulic cone crushing machine increases the eccentricity, high swing frequency and laminated crushing bring higher output, more crushing ratio, and better product shape.

3. Hydraulic cavity cleaning system. The high-efficiency hydraulic cone crusher equipment is a specially designed crushing cavity. It adopts high-energy lamination theory and inputs more energy so that the material crushing occurs not only between the particles and the liner but also between the particles. Therefore, the output is higher, the wearing parts are relatively less worn, the grain shape of the product tends to be cubic, and the content of needle flakes is less.

4. Overload protection, convenient for clearance. Advanced hydraulic technology realizes overload protection and hydraulic adjustment of the discharge port, reducing weight. Provide a clearing system when working in reverse, which is convenient and fast, saving time and manpower.

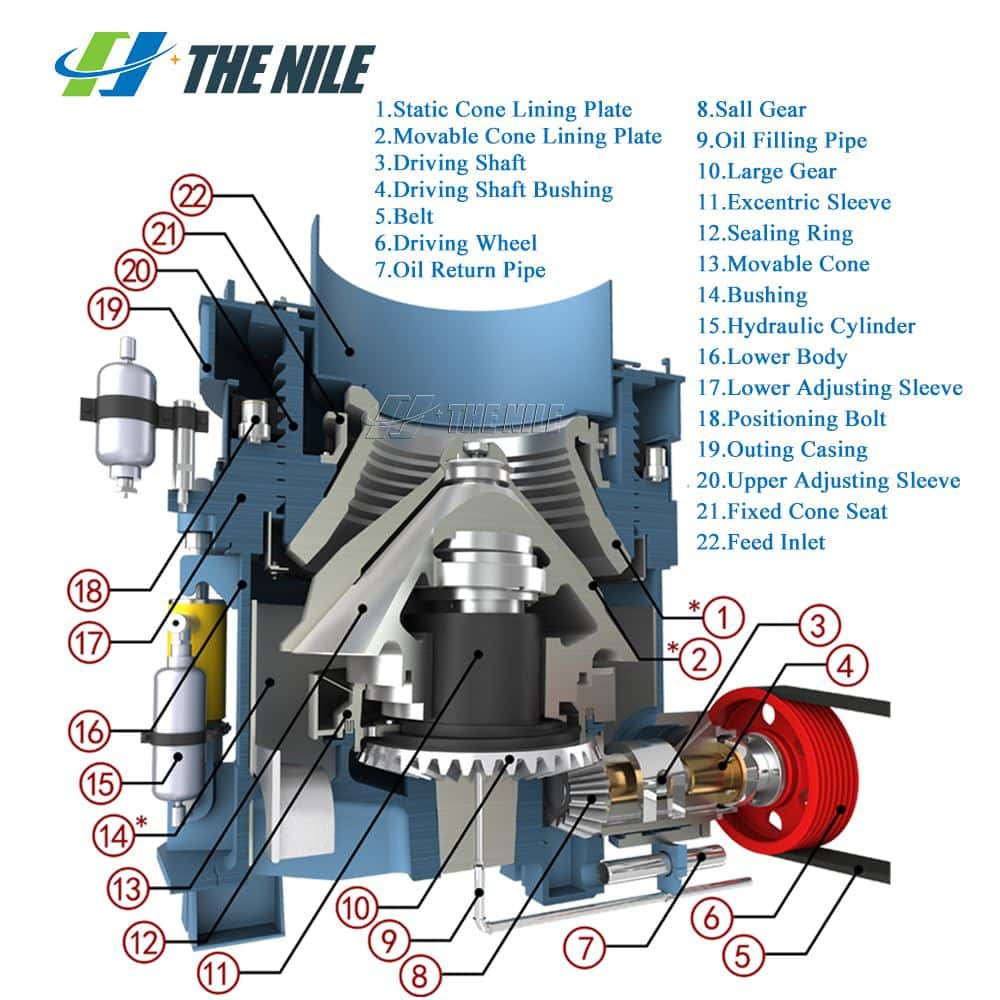

Structural composition of multi-cylinder hydraulic cone crushing machinery

The multi-cylinder hydraulic cone stone crusher machine is mainly composed of a fixed cone part, a movable cone part, an eccentric sleeve part, a transmission part, a frame part, an adjustment ring part, a feed bin part, a discharge port adjustment part, a locking protection cylinder part, and a fun part. , Motor department, hydraulic station, lubrication station, and special tool department.

Packaging and shipping

Company strength

The Nile Machinery Equipment Co., Ltd. is a metallurgical machinery professional machinery factory that specializes in mining equipment research and development, manufacturing, sales, and provides professional mining processing plant workflow design, plant installation, equipment maintenance, and mineral processing technical guidance services. Our products are exported to Africa, Nigeria, Zambia, Zimbabwe, Uganda, Mozambique, South America, the Middle East, and many other countries and regions. At present, we have established our own overseas warehouses in Sudan and Kenya, and we also have our offices in most parts of Africa. You can observe the machinery up close and buy directly, saving transportation costs and time.

Project case: 700 tons of bluestone processing technology per hour in Tanzania

Material: Bluestone

Production capacity: 700 t/h

Auxiliary equipment: 1 cone crusher, 1 jaw crusher, 1 feeder, 2 screening machines, 8 conveyors, and other related equipment.

Client feedback:

I was very excited when I saw technicians from the Nile specifically visit my area to conduct inspections and configure a reasonable production line for me. Because I have also bought machines in China before, and there are very few field trips. The most important thing is that their after-sales service is very good. They will ask about the usage of the machine from time to time and recommend machine maintenance suggestions for me. It is a machinery company with service as its purpose.

| Model | Type of cavity | Min output | Feed opening size | Capacity | Motor power | Moving cone diameter |

| (mm) | (mm) | (t/h) | (kW) | (mm) | ||

| HPY200 | C | 13 | 150 | 100-240 | 160 | 950 |

| F | 6 | 76 | 55-180 | |||

| HPY300 | C | 13 | 225 | 150-300 | 220 | 1160 |

| F | 6 | 86 | 90-240 | |||

| HPY400 | C | 13 | 290 | 190-400 | 315 | 1400 |

| F | 6 | 100 | 108-300 | |||

| HPY500 | C | 13 | 320 | 260-500 | 400 | 1500 |

| F | 6 | 110 | 145-350 | |||

| HPY800 | C | 13 | 350 | 325-800 | 630 | 1800 |

| F | 8 | 120 | 245-450 |