A high-efficiency hydraulic cone stone crusher is a kind of cone crusher, which has many advantages such as a large crushing ratio, high production efficiency, stable structure, and low operating cost. It is a commonly used crushing equipment in the mining industry.

Product description

The high-efficiency cylinder cone crusher machine is mainly used for the medium and fine crushing of materials. It is developed on the basis of the spring cone crusher, and its basic structure is similar to the spring cone crusher. It is used in many industries such as mining, metallurgy, construction, chemical industry, electric power, transportation, and so on.

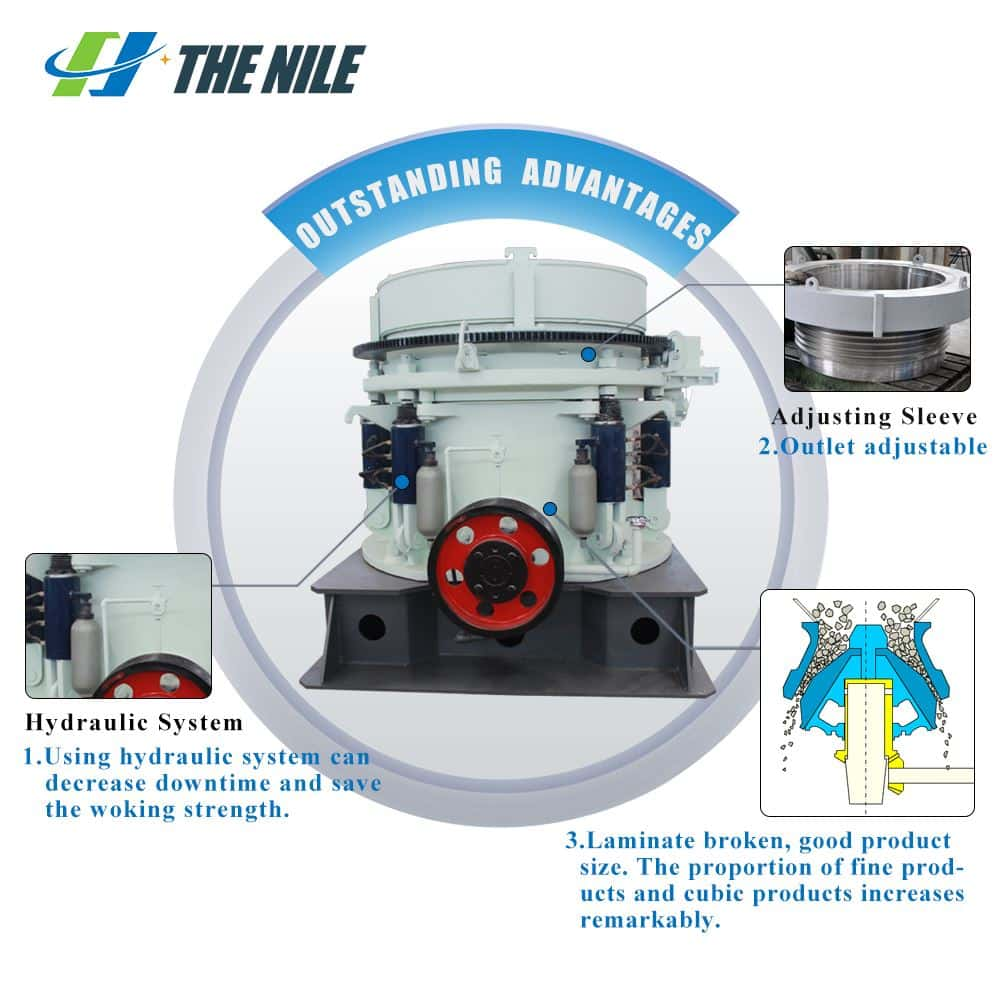

Features of multi-cylinder hydraulic cone crusher for sale

1. The various parts of the whole machine are more reasonable, and the work efficiency is improved;

2. The frame of the multi-cylinder hydraulic cone crusher machine adopts a reinforced full casting structure with long service life;

3. The equipment rotates fast, which improves the efficiency of lamination crushing;

4. The multi-cylinder hydraulic stone cone crushing machine adopts a new hydraulic motor adjustment device;

5. The high-energy hydraulic cone crusher adopts a centralized automatic intelligent control system.

Maintenance of high-efficiency cylinder hydraulic cone stone crushing machine

1. The multi-cylinder hydraulic cone crusher equipment should adopt a closed device, select the appropriate hydraulic oil, and cannot be mixed with other hydraulic oils of different brands.

2. When adding hydraulic oil to the hydraulic system, it must be strictly filtered with a clean oil filter and then added to the hydraulic cylinder. The added oil must be filled with system pipelines and machine components and kept within the range specified by the oil standard.

3. Before using the multi-cylinder hydraulic cone rock crusher machine, the components, pipelines and other systems of the hydraulic system should be cleaned, and the worn parts should be replaced and repaired.

4. During the operation, check the quality of the hydraulic oil regularly. In order to ensure its performance remains unchanged, the hydraulic oil should be replaced regularly to prevent the splashing of water or the entry of dust and fiber debris.

5. Adopt a closed fuel tank device, and equipped with a certain precision air filter at the inlet and outlet.

The equipment selection method is:

(1) The cone stone crusher is widely used for medium and fine crushing of hard materials with a particle size of 0~300mm.

(2) The selection of crushing equipment is related to the physical properties of the processed ore, the production capacity required for crushing, the size of crushed products, and the equipment configuration. The physical properties of ore include ore hardness, density, moisture, clay content, and maximum particle size of the material. According to the ultimate compressive strength of ore, the ore is divided into three types: difficult to crush ore, medium crushable ore, and fragile ore.

(3) The maximum feed size of the cone crusher machine should be less than 85% of the width of the feed opening.

| Model | Type of cavity | Min output | Feed opening size | Capacity | Motor power | Moving cone diameter |

| (mm) | (mm) | (t/h) | (kW) | (mm) | ||

| HPY200 | C | 13 | 150 | 100-240 | 160 | 950 |

| F | 6 | 76 | 55-180 | |||

| HPY300 | C | 13 | 225 | 150-300 | 220 | 1160 |

| F | 6 | 86 | 90-240 | |||

| HPY400 | C | 13 | 290 | 190-400 | 315 | 1400 |

| F | 6 | 100 | 108-300 | |||

| HPY500 | C | 13 | 320 | 260-500 | 400 | 1500 |

| F | 6 | 110 | 145-350 | |||

| HPY800 | C | 13 | 350 | 325-800 | 630 | 1800 |

| F | 8 | 120 | 245-450 |