Hydraulic stone cone crushing machine is a modern high-performance crusher that integrates high swing frequency, optimized cavity shape, and reasonable stroke, which is based on the spring-type cone crusher, based on the principle of laminated crushing and the concept of "more breaking and less grinding".

1. Product introduction

HP series High-efficiencyhydraulic stone cone crusher integrates mechanical, hydraulic, electrical, automation, and other technologies, and is widely used in large-scale concentrators, cement plants, stone plants, highway construction, water conservancy engineering, smelting, construction, and other industries.

2. Application materials:

A multi-cylinder hydraulic cone rock crusher can crush quartz stone, river pebble, calcite, dolomite, granite, basalt, iron ore, limestone, diabase, and other materials.

3. Working principle:

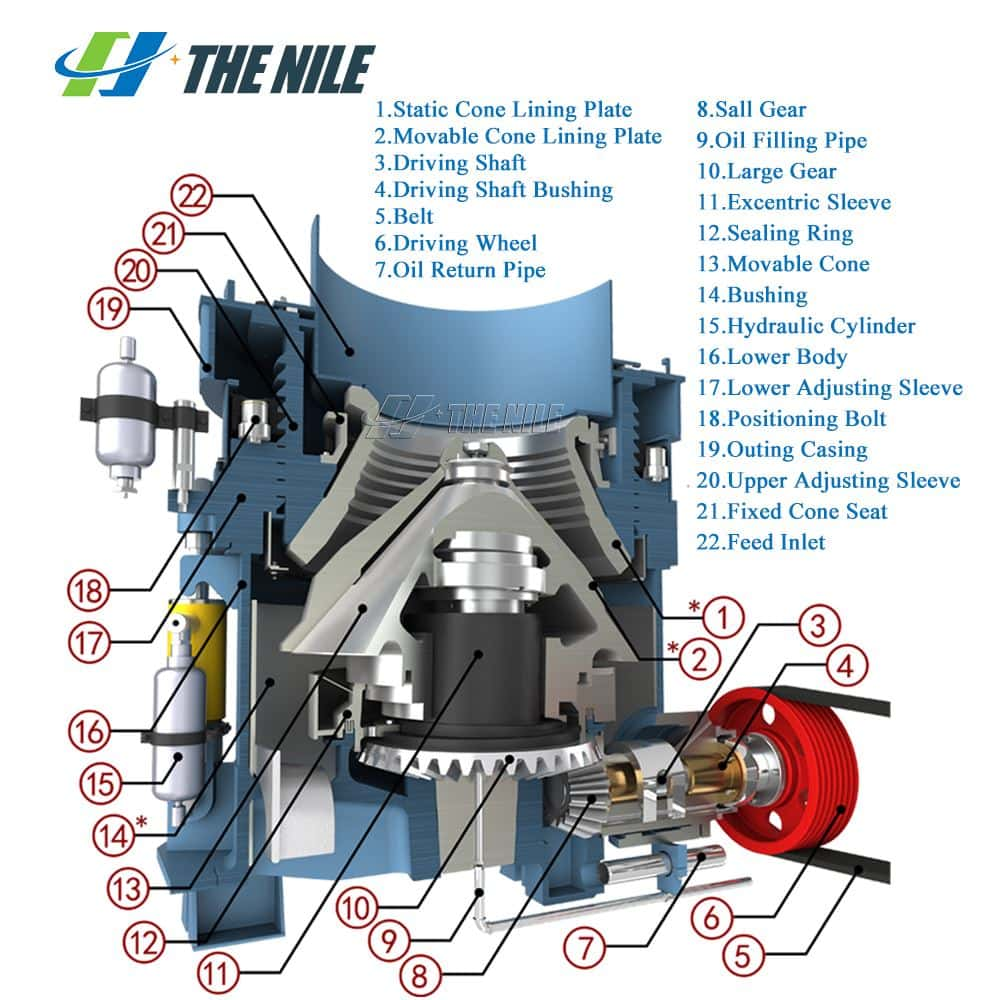

The high-efficiencyhydraulic cone crusherequipmentis mainly composed of seven parts: frame part, support sleeve part, adjusting ring part, moving cone part, eccentric sleeve part, transmission part, and safety device part. A multi-cylinder hydraulic conestonecrusher is a machine that uses the gap (crushing cavity) between two inverted cones to crush materials. When crushing, the moving cone is driven by the eccentric part to continuously approach and leave the fixed cone (a certain position). When it is close, the material is squeezed and bent and crushed. When it leaves, the material is discharged out of the crushing cavity under the action of gravity.

4. Features

1. Large production capacity and high efficiency

The HP series multi-cylinder hydraulic cone crushing machineadopts an advanced spindle fixed structure and the eccentric sleeve rotates around the spindle, which greatly improves the stress state of the spindle. In the case of the same size, it can withstand greater crushing power, plus reasonable The combination of eccentricity, cavity-type, and motion parameters greatly improves the production capacity and work efficiency.

2. Good product size

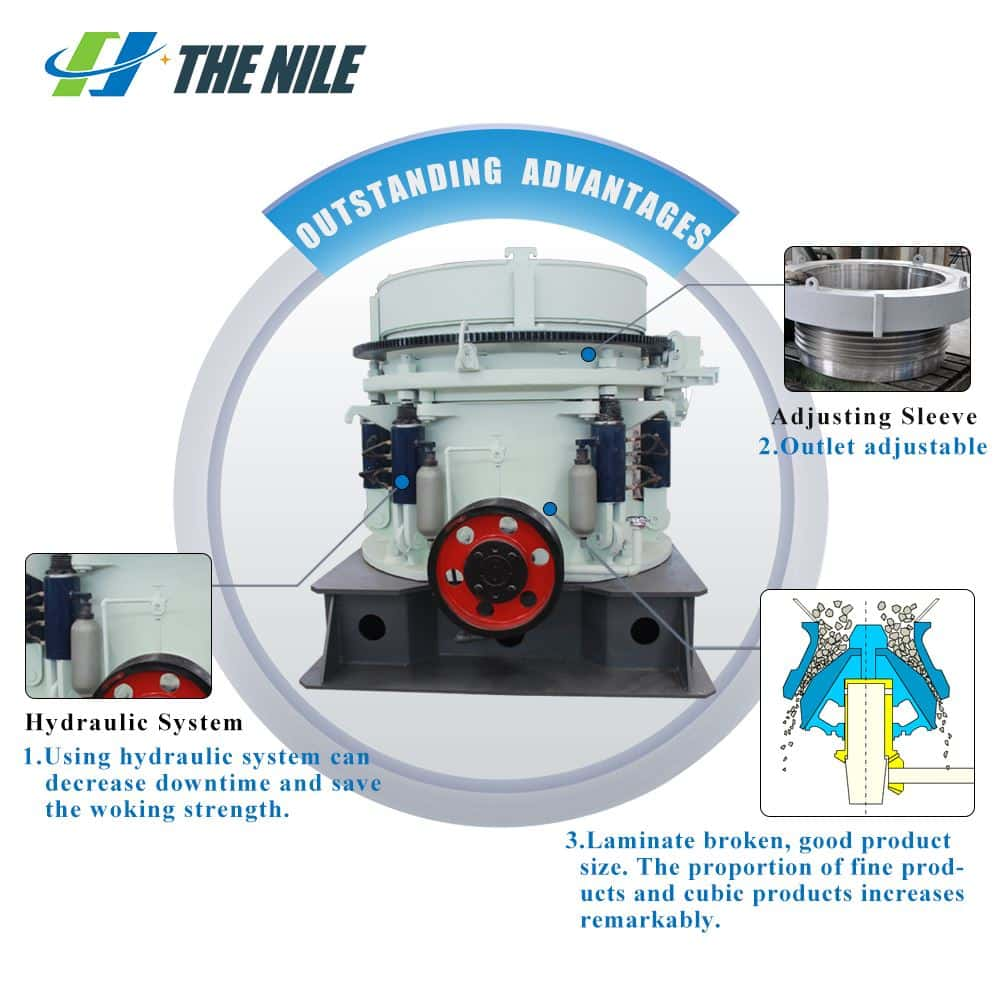

The crushing cavity of the High efficienthydraulic cone crusher machinery adopts the advanced lamination crushing principle, which not only improves the crushing output and efficiency but also improves the product size. The product shape is cubic, which greatly reduces the needle-like products.

3. Convenient and accurate adjustment of the discharge opening

The size of the discharge port can be adjusted by the hydraulic motor, which can be conveniently and accurately controlled and adjusted in the hydraulic station to meet the adjustment of the discharge port during daily operation.

4. Overload protection, convenient for clearance

Our high-energy hydraulic cone crusherfor salewidely uses hydraulic systems. The safety cylinder provides overload protection and an iron release function when the safety cylinder is tensioned in the forward direction and provides the clearing function when working in the reverse direction, which reduces downtime and maintenance time and saves a lot of manpower and material resources.

5. Stable operation and easy maintenance

5. Packaging and transportation:

We will load different sizes of packaging according to different machine sizes, and the normal packaging is a wooden box. For some oversized machines, we will pack them in plastic film first, and then pack them into wooden boards to ensure that the machines are delivered to customers intact.

| Model | Type of cavity | Min output | Feed opening size | Capacity | Motor power | Moving cone diameter |

| (mm) | (mm) | (t/h) | (kW) | (mm) | ||

| HPY200 | C | 13 | 150 | 100-240 | 160 | 950 |

| F | 6 | 76 | 55-180 | |||

| HPY300 | C | 13 | 225 | 150-300 | 220 | 1160 |

| F | 6 | 86 | 90-240 | |||

| HPY400 | C | 13 | 290 | 190-400 | 315 | 1400 |

| F | 6 | 100 | 108-300 | |||

| HPY500 | C | 13 | 320 | 260-500 | 400 | 1500 |

| F | 6 | 110 | 145-350 | |||

| HPY800 | C | 13 | 350 | 325-800 | 630 | 1800 |

| F | 8 | 120 | 245-450 |