Brief Introduction: Overflow ball mill is a kind of beneficiation ball mill, and its name comes from its discharge method of non-mandatory discharge. Only when the pressure in the cylinder reaches a certain degree and the pulp is higher than the lower edge of the hollow shaft at the discharge end, the overflow will occur. Therefore, it is more suitable for secondary grinding with finer grinding fineness and often used for grinding fine ore or concentrate regrinding operations.

Technical Parameters

Model | Ball loading (t) | Feed size(мм) | Size | Performance engine power (kw) | Weight |

Ф900×1800 | 1.4 | ≤20 | 0.075-0.89 | 18.5 | 3.6 |

Ф900×2100 | 1.7 | ≤15 | 0.075-0.83 | 15 | 3.9 |

Ф900×3000 | 2.7 | ≤20 | 0.075-0.89 | 22 | 4.5 |

Ф1200×2400 | 3.5 | ≤25 | 0.075-0.6 | 30 | 11.5 |

Ф1200×2800 | 6.8 | ≤25 | 0.075-0.6 | 37 | 13 |

Ф1200×4500 | 5.5 | ≤25 | 0.074-0.4 | 55 | 13.8 |

Ф1500×3000 | 6.8 | ≤25 | 0.074-0.4 | 75 | 17 |

Ф1500×4500 | 10.5 | ≤25 | 0.074-0.4 | 110 | 21 |

Ф1500×5700 | 15 | ≤25 | 0.074-0.4 | 130 | 24.7 |

Ф1830×3000 | 13 | ≤25 | 0.074-0.4 | 160 | 28 |

Ф1830×3600 | 15 | ≤25 | 0.075-0.4 | 160 | 33.5 |

Ф1830×4500 | 17 | ≤25 | 0.075-0.6 | 185 | 35 |

Ф1830×7000 | 25 | ≤25 | 0.074-0.4 | 210 | 36 |

Ф2100×3600 | 21 | ≤25 | 0.074-0.4 | 185 | 46.8 |

Ф2200×5500 | 30 | ≤25 | 0.074-0.4 | 245 | 48.5 |

Ф2200×6500 | 35 | ≤25 | 0.074-0.4 | 380 | 52.8 |

Ф2200×7500 | 33 | ≤25 | 0.074-0.4 | 380 | 56 |

Ф2400×3000 | 30 | ≤25 | 0.075-0.4 | 245 | 59 |

Ф2400×4500 | 33 | ≤25 | 0.074-0.4 | 380 | 65 |

Ф2700×3600 | 39 | ≤25 | 0.074-0.4 | 400 | 91.3 |

Ф2700×4000 | 40 | ≤25 | 0.074-0.4 | 400 | 94 |

Ф2700×4500 | 48 | ≤25 | 0.074-0.4 | 430 | 102 |

Ф3200×4500 | 65 | ≤25 | 0.075-0.4 | 800 | 137 |

Ф3600×4500 | 90 | ≤25 | 0.074-0.4 | 850 | 158 |

Ф3600×6000 | 110 | ≤25 | 0.074-0.4 | 1250 | 175 |

Ф3600×8500 | 131 | ≤25 | 0.074-0.4 | 1800 | 252 |

Ф4000×5000 | 121 | ≤25 | 0.074-0.4 | 1500 | 203 |

Ф4000×6000 | 146 | ≤25 | 0.074-0.4 | 1600 | 218 |

Working Principle of Overflow Ball Mill

During the operation, the ball mill quipment is supported by rolling bearings, which rotate slowly through the transmission machinery. The material are fed from the feeding end of the cylinder and crushed in the cylinder due to the impact and self-grinding of the steel balls and the ore itself. Due to the continuous feeding of materials, the pressure causes the materials in the cylinder to move from the feeding end to the discharging end, and the pulp is higher than the lower edge of the hollow shaft at the discharging end and overflows spontaneously. The hollow shaft is equipped with reverse spiral blades, which can return the overflowing steel balls and coarse ore back to the overflow ball mill.

Advantages of Overflow Ball Mill

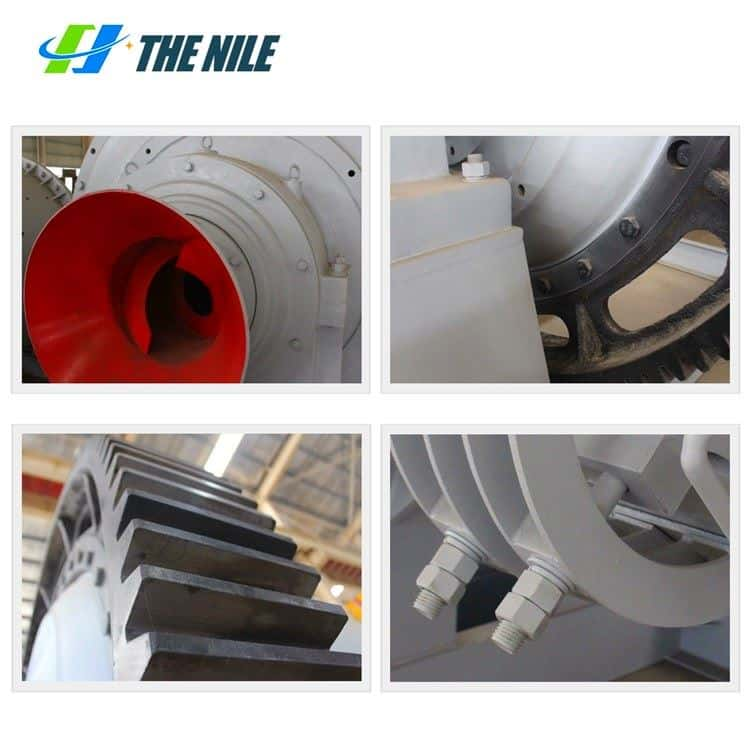

1.Easy to start and run smoothly. Overflow type ball millis equipped with a gas clutch flexible start for easy start, oil mist lubrication device to ensure reliable lubrication of large and small gears, static and dynamic pressure bearings makes stable and reliable operation, slow transmission makes it easy to repair and start.

2.The structure is simple and convenient for maintenance. Because the discharge pipe is cast with reverse thread, large ore and steel balls are not easy to discharge out of the machine. The small overflow ball mill is equipped with jacking device, which makes users maintenance and repair work more convenient.

3.The lining plate is optional and has high wear resistance. The lining board can be selected according to different grinding materials. The lining board material includes metal lining board, rubber lining board, cast stone lining board, etc. The lining board shape can choose flat liner, corrugated liner, convex edge Liner, bead liner, step liner, hemispherical liner, etc.

4.Overflow type ball mill can be divided into dry grinding, wet grinding or mixed fine grinding. It also adopts advanced controllable feeding and discharging technology, combined with the actual grinding material and equipped with appropriate grinding body, and change the traditional surface contact to line contact, so that the discharging particle size is more uniform and the output is higher.

5.The material of cylinder is reliable and the performance of components is advanced. The cylinder of flow type ball mill is made of steel plate with thickness of 15-36mm. Both ends of the cylinder are welded with flanges made of cast steel, and the end covers 2 and 3 are connected with the flanges with bolts. Its precision machining and matching greatly improve the wear resistance of the components.

6. Low labor intensity and saving manpower. When the overflow type ball mill is working, its stopping time is very short, and the machine vibration is small during operation, which does not affect the life of the equipment. What is more, the overflow type ball mill has low labor intensity and saves manpower for customers.

Technical Parameters of Overflow Ball Mill

Model | Ball loading (t) | Feed size(мм) | Size | Performance engine power (kw) | Weight |

Ф900×1800 | 1.4 | ≤20 | 0.075-0.89 | 18.5 | 3.6 |

Ф900×2100 | 1.7 | ≤15 | 0.075-0.83 | 15 | 3.9 |

Ф900×3000 | 2.7 | ≤20 | 0.075-0.89 | 22 | 4.5 |

Ф1200×2400 | 3.5 | ≤25 | 0.075-0.6 | 30 | 11.5 |

Ф1200×2800 | 6.8 | ≤25 | 0.075-0.6 | 37 | 13 |

Ф1200×4500 | 5.5 | ≤25 | 0.074-0.4 | 55 | 13.8 |

Ф1500×3000 | 6.8 | ≤25 | 0.074-0.4 | 75 | 17 |

Ф1500×4500 | 10.5 | ≤25 | 0.074-0.4 | 110 | 21 |

Ф1500×5700 | 15 | ≤25 | 0.074-0.4 | 130 | 24.7 |

Ф1830×3000 | 13 | ≤25 | 0.074-0.4 | 160 | 28 |

Ф1830×3600 | 15 | ≤25 | 0.075-0.4 | 160 | 33.5 |

Ф1830×4500 | 17 | ≤25 | 0.075-0.6 | 185 | 35 |

Ф1830×7000 | 25 | ≤25 | 0.074-0.4 | 210 | 36 |

Ф2100×3600 | 21 | ≤25 | 0.074-0.4 | 185 | 46.8 |

Ф2200×5500 | 30 | ≤25 | 0.074-0.4 | 245 | 48.5 |

Ф2200×6500 | 35 | ≤25 | 0.074-0.4 | 380 | 52.8 |

Ф2200×7500 | 33 | ≤25 | 0.074-0.4 | 380 | 56 |

Ф2400×3000 | 30 | ≤25 | 0.075-0.4 | 245 | 59 |

Ф2400×4500 | 33 | ≤25 | 0.074-0.4 | 380 | 65 |

Ф2700×3600 | 39 | ≤25 | 0.074-0.4 | 400 | 91.3 |

Ф2700×4000 | 40 | ≤25 | 0.074-0.4 | 400 | 94 |

Ф2700×4500 | 48 | ≤25 | 0.074-0.4 | 430 | 102 |

Ф3200×4500 | 65 | ≤25 | 0.075-0.4 | 800 | 137 |

Ф3600×4500 | 90 | ≤25 | 0.074-0.4 | 850 | 158 |

Ф3600×6000 | 110 | ≤25 | 0.074-0.4 | 1250 | 175 |

Ф3600×8500 | 131 | ≤25 | 0.074-0.4 | 1800 | 252 |

Ф4000×5000 | 121 | ≤25 | 0.074-0.4 | 1500 | 203 |

Ф4000×6000 | 146 | ≤25 | 0.074-0.4 | 1600 | 218 |