Ball mill is a kind of grinder, used to grind materials into a very fine powder, mainly used in the mineral processing industry. According to requirements, the ball mill machine can grind various ores and other materials wet or dry.

Product Introduction

A dry ball grinding mill is the key equipment for crushing materials after crushing. The dry ball mill equipment is a cylindrical tube mill, which is widely used in the dry mill production of various non-metallic materials such as cement and coal powder. It can grind feldspar, glass, dolomite, quartz, silica sand, etc.

Working principle

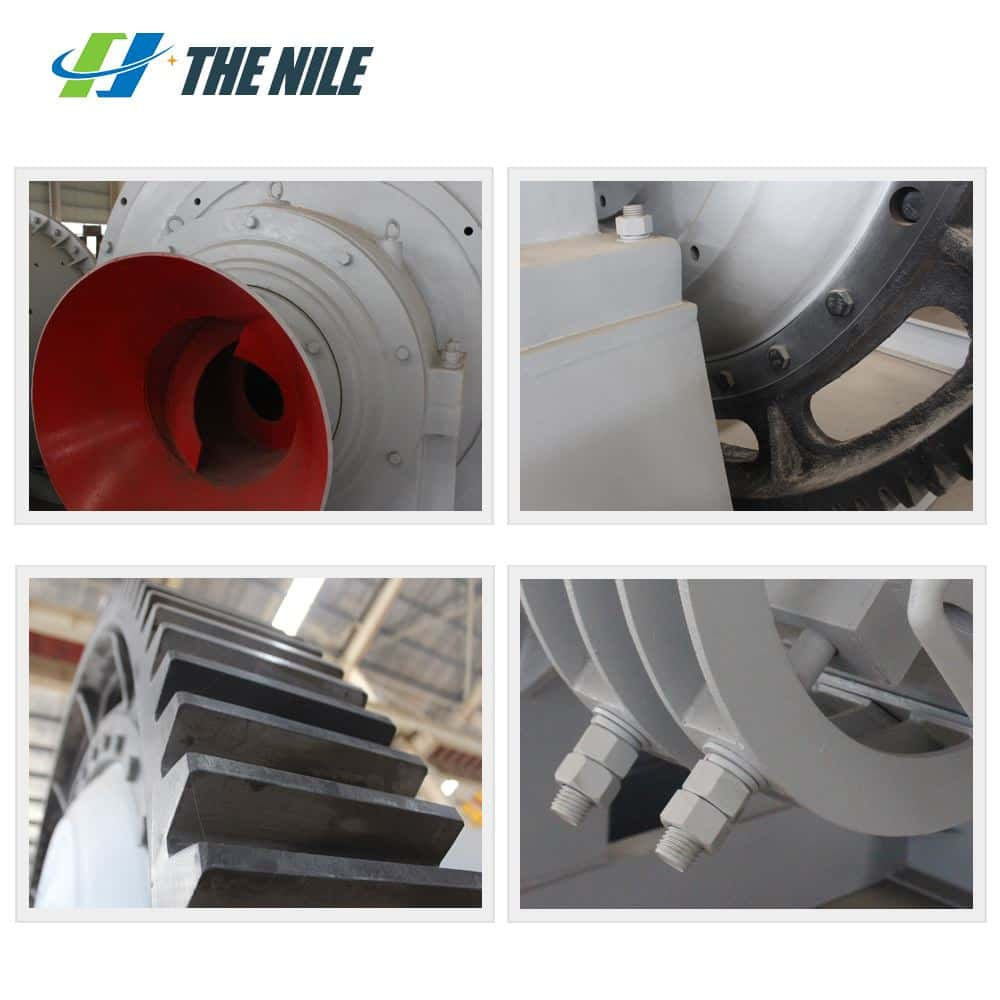

The material is fed into the first chamber of the dry ball mill machine through the hollow shaft of the feeding device. The chamber has a step liner or a corrugated liner, which contains steel balls of different specifications. The cylinder rotates to generate centrifugal force to bring the steel balls to a certain level. Falling after the height, will have a heavy blow and grinding effect on the material. After the material reaches the rough grinding in the first warehouse, it enters the second warehouse through the single-layer partition board. The warehouse is lined with flat liners and steel balls to further grind the materials. The powder is discharged through the unloading grate to complete the grinding operation.

Features

Features

1. Long service life, low pollution

The sliding bearing of the ball mill grinding machine is changed to a rolling bearing, which not only has a large carrying capacity and a long service life but can be increased by more than 5 times compared with a sliding bearing. The maintenance amount of the main bearing of the ball millmachineryis reduced, the operating environment is improved, and there is no oil pollution.

2. Large single machine capacity

Compared with ordinary ball mills, dry ball mills greatly reduce the power of the original motor, reduce installed capacity, improve work efficiency, and reduce reactive power loss.

3. The structure is simple and the maintenance is convenient.

Thegrindingball mill is mainly composed of a feeding part, a discharging part, a rotating part, and a transmission part (reducer, small transmission gear, motor, electric control). Convenient installation and debugging, simple operation.

4. Low power consumption

The starting current of the ball milldeviceis low, the starting time is short, and the starting is flexible. The normal working current is reduced by 20%-30% to achieve the purpose of power-saving

Care instructions

⒈The operation and maintenance personnel of the ball millequipment should be familiar with the structure and performance of the crushing equipment and the names, specifications, and functions of the various components.

⒉Operators must follow the "four determinations" principle, and require lubrication for each part marked in the lubrication diagram, and must not use untreated waste oil to keep the lubrication points clean.

⒊ During operation, check that the temperature of each bearing does not exceed 60℃, and check whether the bolts of each part are loose, whether there is abnormal sound, whether the water supply to the mine is uniform, whether there is slurry leakage in the cylinder, and whether the motor current and voltage are normal. Whether the protective cover of the transmission part is in good condition.

⒋Keep the equipment environment sanitary and clean, except for the running part, all other parts must be handled at any time.

Company strength

The Nile Company has a professional salesman team and a strong design team, focusing on the research and development of crushing equipment, machine-made sand production equipment, ore dressing equipment, and gold dressing equipment. The products are sold at home and abroad, and overseas warehouses are set up in Sudan and Kenya.

| Model | Ball loading (t) | Feed size(мм) | capacity | Performance engine power (kW) | Weight |

| (t/h) | (T) | ||||

| Ф1200×4500 | 6.5 | ≤25 | 1.4-2 | 45 | 13.1 |

| Ф1500×5700 | 13 | ≤25 | 3.5-4.5 | 130 | 24 |

| Ф1830×6400 | 21.6 | ≤25 | 5.5-6.5 | 210 | 38 |

| Ф1830×7000 | 23.5 | ≤25 | 6-7 | 210 | 43 |

| Ф2200×6500 | 31.5 | ≤25 | 8-10 | 380 | 50.2 |

| Ф2200×7500 | 36 | ≤25 | 10-11 | 380 | 53.2 |

| Ф2200×8000 | 39 | ≤25 | 10-12 | 380 | 55 |

| Ф2200×9500 | 46 | ≤25 | 14-16 | 475 | 65 |

| Ф2400×11000 | 64 | ≤25 | 19-21 | 680 | 99.2 |

| Ф2400×13000 | 75.5 | ≤25 | 21-23 | 800 | 115.2 |

| Ф2600×13000 | 122 | ≤25 | 28-32 | 1000 | 148 |

| Ф3000×12000 | 109 | ≤25 | 32-35 | 1250 | 168.6 |

| Ф3000×13000 | 118 | ≤25 | 34-37 | 1400 | 172.3 |

| Ф3200×13000 | 185 | ≤25 | 45-50 | 1600 | 218 |

| Ф3800×13000 | 189 | ≤25 | 60-62 | 2500 | 286 |

| Ф4000×13000 | 231 | ≤25 | 85-87 | 3550 | 320 |