VSI sand maker machines are widely used in fine crushing and coarse grinding of cement, refractory materials, construction aggregates, artificial sand, and various metallurgical slags. It has many advantages such as a high degree of automation, long service life, and high work efficiency.

Product Introduction

VSI sand maker machine is equipment in the field of artificial sand making and stone shaping. It can make all kinds of rocks, gravel, and river pebbles into construction sand with various grain sizes, and provide high-quality sand and gravel aggregates for highways, high-speed railways, high-rise buildings, concrete mixing plants, and other industries. Such as cobblestone, granite, limestone, basalt, etc.

The working principle of the VSI sand maker machine

First, the material enters the distributor. The high-speed rotating turbine in the distributor can generate strong pressure and impact force, and throw the raw material block at a hundred times the speed to form an impact and cause the first part of crushing. After being thrown and impacted, the raw materials form a back and forth cycle in the vortex cavity. The crushing effect will gradually increase, and while passing through the internal conduction, it can also cause collision and friction between the raw materials, so that the particles of the raw materials become smaller and the surface is more compact. smooth. After this kind of decomposition, the material block will enter the feed inlet. Below the feed inlet, a high-speed rotating member will throw the material and bounce back to form repeated collisions with the newly entered raw material, which further causes the material. Smashed, and then discharged with the discharge port of the lower half.

Features of sand maker machine

Features of sand maker machine

1. The sand manufacturing machine has two functions of rough grinding and fine grinding, which can meet the different needs of users.

2. The impeller cavity of the sand stone-making machine is deep, the stone throughput is large, and the output is large.

3. The finished product has a good shape, has a certain shaping effect, and the fineness modulus is adjustable.

4. The airflow inside the sand-making machine circulates automatically, with less dust and low noise, which is more economical and environmentally friendly.

5. The base of the sand-making machine for sale can form a protective layer and is durable.

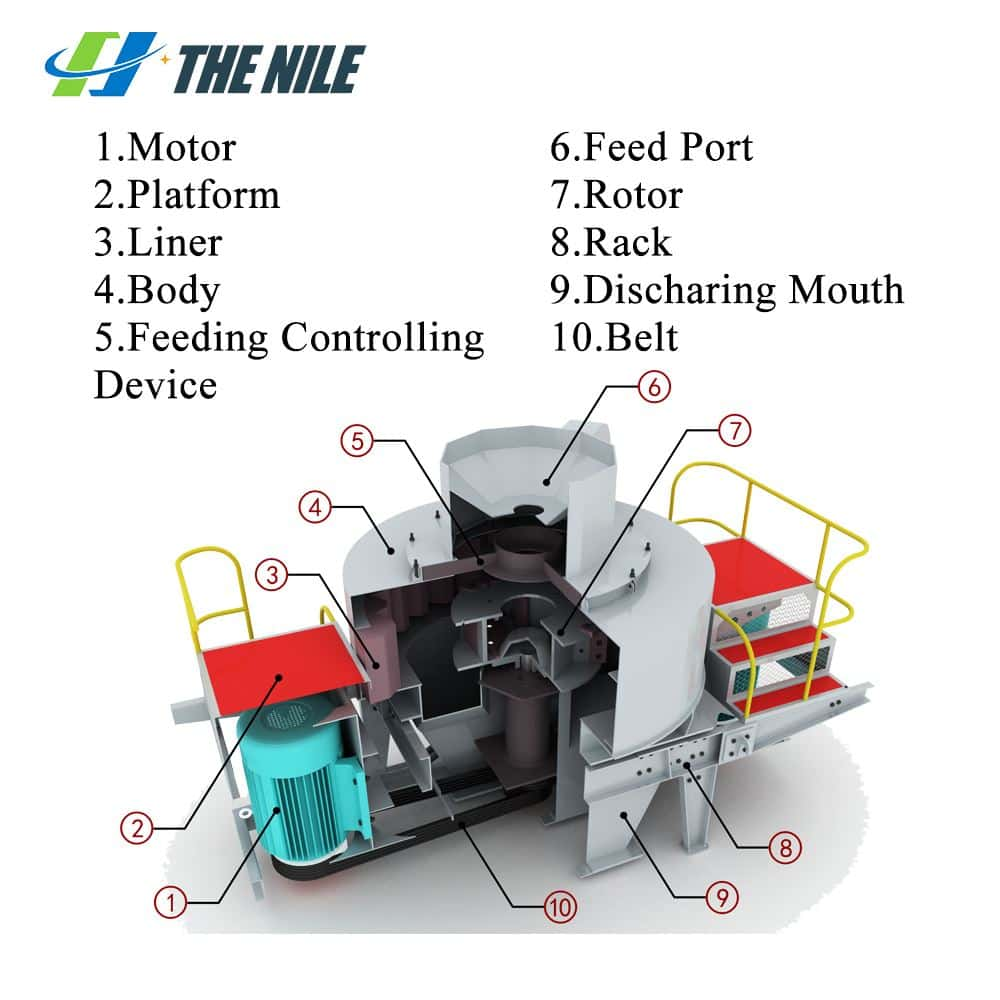

Components of VSI sand maker machine

The sand-making machine is mainly composed of feed, spindle assembly, distributor, cyclone crushing cavity, impeller, base, transmission device and bracket, lubrication system, and motor.

Our workshop

Customer visiting

The product packaging

Company strength

The Nile Machinery Equipment Co., Ltd. is a metallurgical machinery professional machinery factory that specializes in mining equipment research and development, manufacturing, sales, and provides professional mining processing plant workflow design, plant installation, equipment maintenance, and mineral processing technical guidance services. Our products are exported to Africa, Nigeria, Zambia, Zimbabwe, Uganda, Mozambique, South America, the Middle East, and many other countries and regions. At present, we have established our own overseas warehouses in Sudan and Kenya, and we also have our offices in most parts of Africa. You can observe the machinery up close and buy directly, saving transportation costs and time.

Project case: Sand making production line for road construction

Show details: Sand-making line including vibrating feeder, jaw crusher, cone crusher, VSI sand-making machine, sand washing machine, vibrating screen, and belt conveyor. In this line, we use a jaw crusher as the first crushing machine, vibrating screen to ensure that the discharge size meets the requirements. And if some of the discharge sizes are too big, will be transported to the cone crusher as the secondary crushing. Then the materials are transported to the VSI sand-making machine and sand washing machine. Finally, materials of different sizes that meet the requirements will be transported to different places through the belt conveyor.

| Model No. | VSI7611 | VSI8518 | VSI9526 | VSI1140 | VSI1145 | |

| Capacity | Cascade Feeding | 120-180 | 200-260 | 300-380 | 450-520 | 500-640 |

| (t/h) | Full Central Feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-360 |

| Max. Feeding size(mm) | Soft Material | 35 | 40 | 45 | 50 | 50 |

| Hard Material | 30 | 35 | 40 | 45 | 45 | |

| Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1100-1310 | |

| Model of Motor | Y250M-4 | Y280M-4 | Y315M-4 | Y315L2-4 | Y315L2-4 | |

| Double Motor Power | 55*2 | 90*2 | 132*2 | 200*2 | 220*2 | |

| Weight (t) | 10 | 12 | 16 | 25.6 | 27.5 | |