VSI sand making equipment, also known as impact crusher, is widely used in fine crushing and coarse grinding of cement, refractory materials, construction aggregates, artificial sand, and various metallurgical slags.

Product description

The sand making machine is a high-efficiency and high-quality sand-making equipment developed on the basis of the principle of the "stone hitting stone" crusher and combined with the actual needs of domestic and foreign customers for sand production. It can make all kinds of rocks, sandstones, and river pebbles into construction sand with various grain sizes, and provide high-quality sand and gravel aggregates for the mining industry.

The working principle of the VSI sand stone maker

The material falls vertically from the upper part of the machine into the high-speed rotating impeller. Under the action of high-speed centrifugal force, it will shunt with another part in the form of an umbrella. The material around the impeller produces high-speed impact and is broken. The eddy currents are formed between the casings, and they are crushed by multiple collisions and frictions and are discharged vertically from the lower part, and the required finished product size is sieved through the screening equipment.

Features of VSI sand making equipment

1. Long service life. The raw material of the sand making machine is high-strength cast iron, the parts are not easy to be damaged, and the mechanical properties are good.

2. The finished product has a good grain shape. The sand stone maker has two functions of rough grinding and fine grinding, which can control the particle size of the material and the depth of the impeller cavity, which can reshape the material, and the finished sand has a good grain shape.

3. Energy saving and environmental protection. The internal airflow circulates automatically, the noise is low, the dust is small, and the environmental pollution is small.

4. Large processing capacity and high work efficiency. Compared with sand-making equipment of the same power, the output of VSI sand-making equipment is increased by 30%, the processing capacity is large and it is not easy to be damaged.

5. Durable and wear-resistant. During the production process of the sand making machine, the base can form a protective bottom layer, the machine body is wear-free, durable, and highly automated, reducing manual operation time.

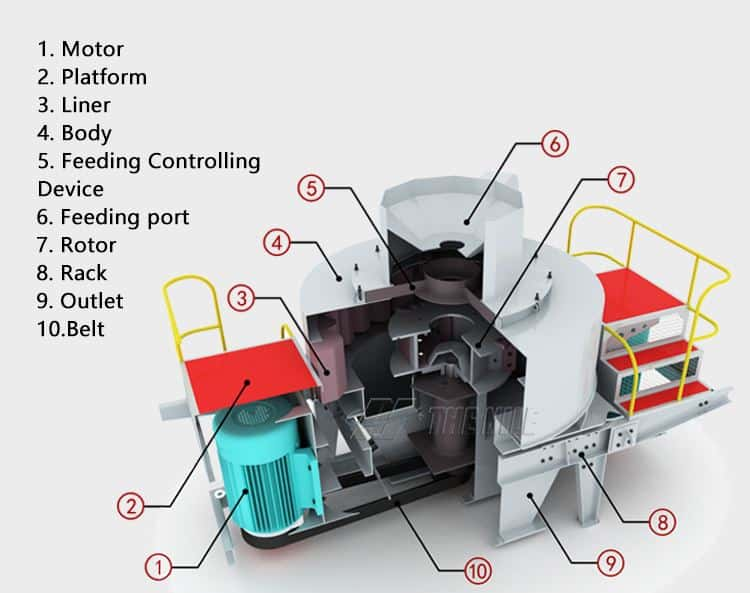

The structure of the sand making machine for sale

The VSI sand making equipment is mainly composed of feeder, distributor, impeller, main shaft assembly, cyclone crushing cavity, transmission device and support, base, lubrication system, and motor.

Packaging and shipping

Company strength:

The Nile Machinery is an engineering general contracting comprehensive service company with mining machinery production and export as its main business. Since its establishment, it has built a large number of influential international projects and has been widely recognized by the country where it has served many countries and regions. At present, it operates various types of equipment such as stone crushing equipment, gold beneficiation equipment, sand making equipment, industrial grinding equipment, and mineral ore beneficiation equipment. The business areas cover metallurgy, mining, transportation, building materials, electric power, environmental protection, chemicals, etc.

Project case: sand production line for highway construction

Detail display: The sand making line includes a vibrating feeder, jaw crusher, cone crusher, VSI sand making machine, sand washing machine, vibrating screen, and belt conveyor. On this production line, we use the jaw crusher as the first crusher, and the vibrating screen ensures that the discharge particle size meets the requirements. And if part of the discharged material is too large in size, it will be transported to the cone crusher for secondary crushing. Then the material is transported to VSI sand making machine and sand washing machine. Finally, materials of different sizes that meet the requirements will be transported to different places through the belt conveyor.

| Model No. | VSI7611 | VSI8518 | VSI9526 | VSI1140 | VSI1145 | |

| Capacity | Cascade Feeding | 120-180 | 200-260 | 300-380 | 450-520 | 500-640 |

| (t/h) | Full Central Feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-360 |

| Max. Feeding size(mm) | Soft Material | 35 | 40 | 45 | 50 | 50 |

| Hard Material | 30 | 35 | 40 | 45 | 45 | |

| Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1100-1310 | |

| Model of Motor | Y250M-4 | Y280M-4 | Y315M-4 | Y315L2-4 | Y315L2-4 | |

| Double Motor Power | 55*2 | 90*2 | 132*2 | 200*2 | 220*2 | |

| Weight (t) | 10 | 12 | 16 | 25.6 | 27.5 | |