The fine sand recycling equipment for sale effectively solves the problem of fine sand recovery and is a new type of environmental protection equipment. The fine sand recycling machine has many advantages such as low energy consumption, high work efficiency, long service life, and large processing capacity.

Product introduction:

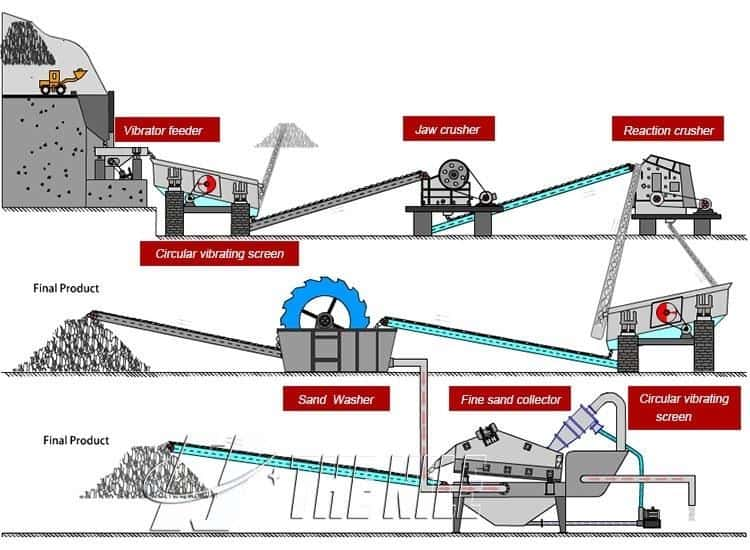

high recycling rate fine sand collecting machine is mainly used in the process of fine sand recovery of wastewater in the aggregate production line and sand selection of mine tailings. It is widely used in fine sand and mud purification, sand and gravel processing system of hydropower stations, artificial sand production lines, and environmental engineering, etc., it effectively solving the problem of fine sand recovery.

Features:

1. The fine sand recycling equipment for sale adopts an enlarged and widened design, with large capacity, low energy consumption, and high efficiency.

2. The box body adopts thickened and reinforced high-quality steel plate, which has longer service life and low failure rate.

3. The fine particles are fully recovered, which reduces the cost of cleaning the sedimentation tank.

4. Manufacturers ' fine sand recycling machine reduces the pollution of wastewater to the environment and waste of resources and turns the sediment in the wastewater into treasure.

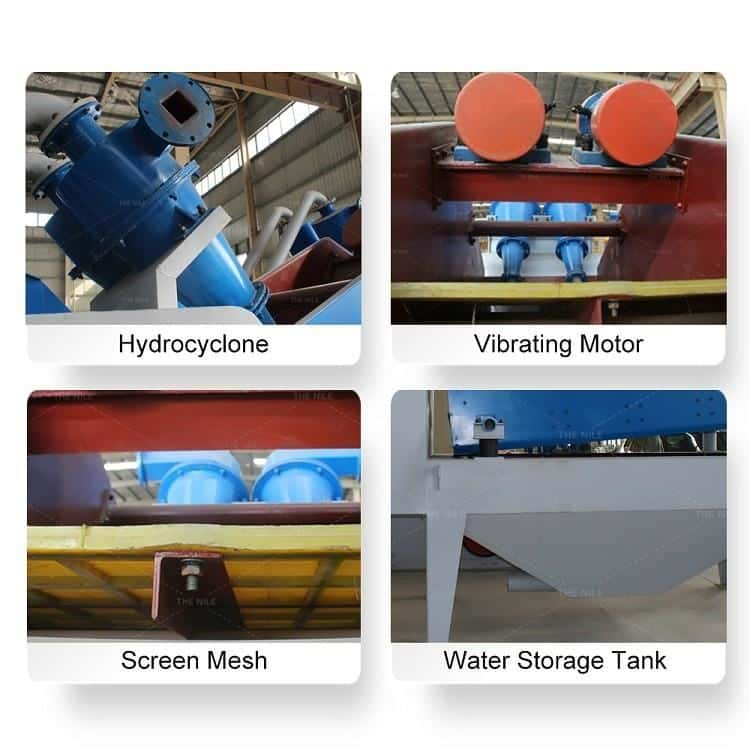

The structure of the fine sand recovery equipment for sale:

The fine sand recovery equipment is mainly composed of a motor, a vacuum high-pressure pump, a sediment separator, a dewatering screen, a cleaning tank, and a return box. The separation principle of the silt separator is centrifugal sedimentation. It is produced and processed from highly wear-resistant materials and has the advantages of high elasticity and high wear resistance. The fine sand recycling machine of the Nile Company adopts the latest type of vacuum high-pressure pump.

Purpose of fine sand recycling machine:

The fine sand recycling equipment for sale can be used in the dehydration link of the ceramic raw material processing system, the tailings recovery treatment of the concentrator, the quartz sand processing system, the sand, and gravel processing system of the hydropower station, etc., and can effectively solve the problem of fine sand and fine material recovery. Compared with the vacuum filter, the fine sand recovery machine has the advantages of less investment and lower power consumption.

Overseas service:

1. We have engineers in Kenya, Sudan, and Uganda, they will provide professional installation and training skills.

2. We have factories and warehouses in Kenya and China. When your wearing parts are damaged, you can go directly to the factory to buy them, which is convenient and quick.

3. Our products have been distributed all over China and exported to Europe, America, Asia, and African countries. Our sales managers and engineers know the local situation very well, and we will provide you with the most suitable solution.

| Model | Capacity | Separator size | Power(kW) | Sieve size W*L(mm) | Weight(kg) |

| NX250 | ≤60 | 250 | 13.2 | 900*1800 | 1460 |

| NX300 | ≤75 | 300 | 17.2 | 900*1800 | 1510 |

| NX350 | ≤100 | 350 | 20.7 | 900*1800 | 1700 |

| NX550 | ≤120 | 250*2 | 26.4 | 1200*2400 | 2170 |

| NX650 | ≤150 | 300*2 | 34.4 | 1200*2400 | 2500 |

| NX750 | ≤200 | 350*2 | 41.4 | 1500*3000 | 2850 |

| NX900 | ≤225 | 300*3 | 51 | 1800*3750 | 3500 |