The fine sand recycling machine for sale attracts a new type of environmental protection equipment developed by foreign advanced technology. It is widely used in fine sand and mud purification, hydropower station sand and gravel processing systems, glass material processing systems, artificial sand production lines, coarse slime recovery, environmental engineering (mud purification), and so on, effectively solve the problem of fine sand recovery.

Product description

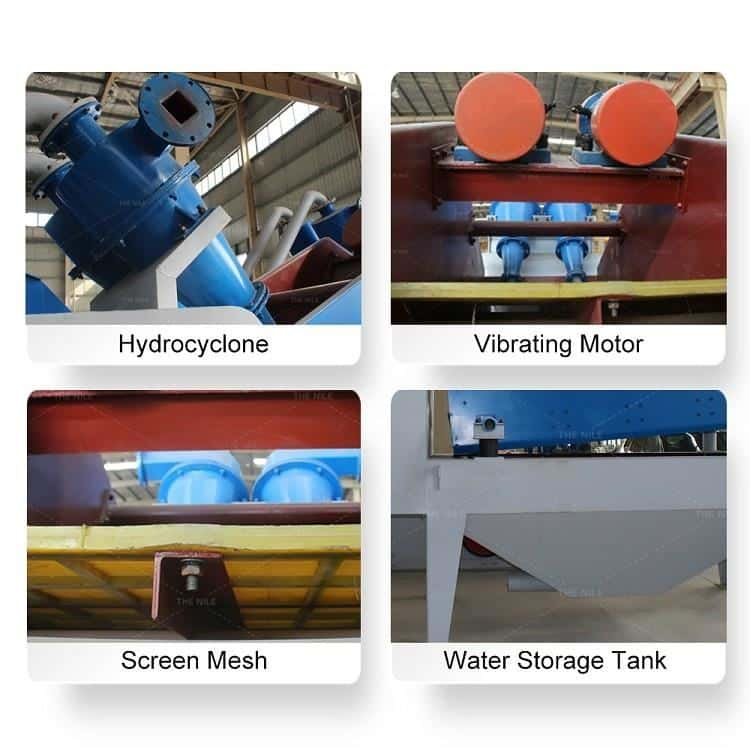

The fine sand recycling machinery is mainly a device developed for the dehydration, disintermediation, and desliming of slurry materials. This machine greatly solves the problem of fine sand loss in the sand-making industry. The main function of the fine sand recycling equipment is to clean, dehydrate and classify sand and gravel. The main function of the fine sand recycling machine is to clean, dehydrate and grade the sand, which can well recover a large amount of fine sand lost by the sand washing machine in the traditional sand making industry, improve the economic benefit and reduce the treatment cost of tailings.

Working principle of fine sand recycling machine for sale

The pump slurry sand-water mixture is transported to the sand high-pressure separator, the tailings concentrated by the centrifugal classification are provided to the dewatering screen through the grit settling nozzle. After the dewatering screen is dehydrated, the tailings and water are effectively separated, and a small number of tailings and mud are returned to the return box. Back to the cleaning tank, when the liquid level of the cleaning tank is too high, it will be discharged through the discharge port

Features of fine sand recycling machine

1) The impurity of sand is reduced, the quality is improved, and the benefit is increased.

2) Low energy consumption rate, energy-saving, and environmental protection.

3) Simple structure and convenient transportation.

4) low failure rate and long service life.

5) The fine sand recovery equipment can not only reduce the loss rate of fine sand but also reduce the stone powder content in the tailwater.

FAQ:

Q1: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

Q2: What about the quality of your products?

A: Our products are manufactured strictly in accordance with national and international standards, and we will test every piece of equipment before shipment. We guarantee if the quality of products is different from the description we described before your placing order, we promise a 100% refund.

Q3: Is the price of products reliable?

A: Yes, we are a manufacturer and we have the strength to give you the lowest price compared with other dealers. However, we have the policy that "According to the quantity order, we will offer the lowest price as possible with our utterly honest attitude towards business ".

| Model | Capacity | Separator size | Power(kW) | Sieve size W*L(mm) | Weight(kg) |

| NX250 | ≤60 | 250 | 13.2 | 900*1800 | 1460 |

| NX300 | ≤75 | 300 | 17.2 | 900*1800 | 1510 |

| NX350 | ≤100 | 350 | 20.7 | 900*1800 | 1700 |

| NX550 | ≤120 | 250*2 | 26.4 | 1200*2400 | 2170 |

| NX650 | ≤150 | 300*2 | 34.4 | 1200*2400 | 2500 |

| NX750 | ≤200 | 350*2 | 41.4 | 1500*3000 | 2850 |

| NX900 | ≤225 | 300*3 | 51 | 1800*3750 | 3500 |