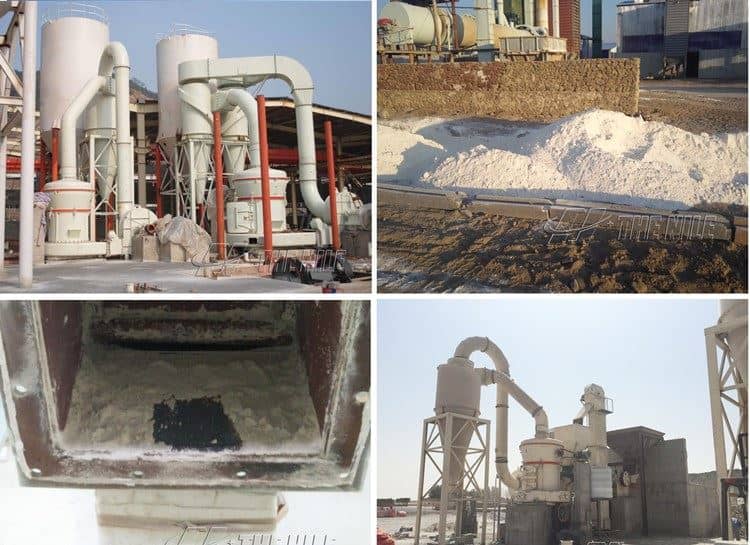

The Installation of Raymond Grinding Mill. Raymond mill equipment is indispensable equipment for grinding ore and stone materials. So how to help our customers complete the installation of it?

1. Carefully read the foundation map about Raymond grinding plant, draw out the external lines of the excavated pits, and then focus on determining the location of the host.

2. Find out the two vertical centerlines of the host of Raymond grinding mill and lay four wooden stakes on the host of the digging pit. Then determine the centerline of other mining equipment with the centerline of the roller mill as a benchmark and lay the stakes in the pit outside.

3. According to the requirements of the drawings, the depth of digging of the host of Raymond mill is ensured. The depth of other machines can be determined according to the actual conditions of the foundation.

4. Place bolts, reducers, blowers, hoisting pits that various places and ensure the relative position of the holes of Raymond grinding mill, and place ribs on the Raymond mill and blower.

5. When the concrete is poured to a certain height, check whether the wooden mold of Raymond mill is displaced. After confirming that the position is correct, continue casting and vibrating the vibrator to ensure Raymond mill quality.

6. In the process of Raymond mill’s lifting and installation, maybe the host shaft will move up. It does move up if the belt pulley and the cover gap is less than 12mm. At this time users must use a sledgehammer to hit the center of the upper end of the plum rack to reset the center axis. Otherwise, when the Raymond mill works for a certain period of time, the central axis is reset under the effect of gravity and the two pulleys are inconsistent in level, which may cause belt damage. Therefore, after the Raymond mill is in position, users must check the clearance between the pulley and the gland.

7. The blower casing of Raymond mill uses the internal air inlet of the main air reservoir as the reference for the fan casing and the blower seat. Once in place, the second grouting can be performed. When the second grouting is close to the bottom plane of the Raymond mill base, the following specifications are used: 250 x 250 steel plates of different thickness are placed on the anchor bolts of the Raymond mill and filled with grout.