Product introduction Hydraulic cone crusher can be used to crush hard and medium hard minerals, rocks, iron ores, limestone, copper ores, quartz, granite, sandstones, etc... In a whole production line, the cone crusher is usually used for secondary or tertiary crushing process, or first...

Product introduction

Hydraulic cone crusher can be used to crush hard and medium hard minerals, rocks, iron ores, limestone, copper ores, quartz, granite, sandstones, etc... In a whole production line, the cone crusher is usually used for secondary or tertiary crushing process, or first crushing.

Outstanding Features

1.Reasonable structure, advanced crushing principle, and technical parameters, reliable operation, lower operating costs

2. With large crushing force, high efficiency, high yield

3. Convenient and reliable hydraulic system, to provide safe and effective overload, as compared with the conventional method of the system greatly reduces the operation time, saving manpower

4.A variety of crushing chamber to meet a wide range of product size requirements

5.Hydraulic adjustment, hydraulic clean cavity setting, a much higher degree of automation

Working principle

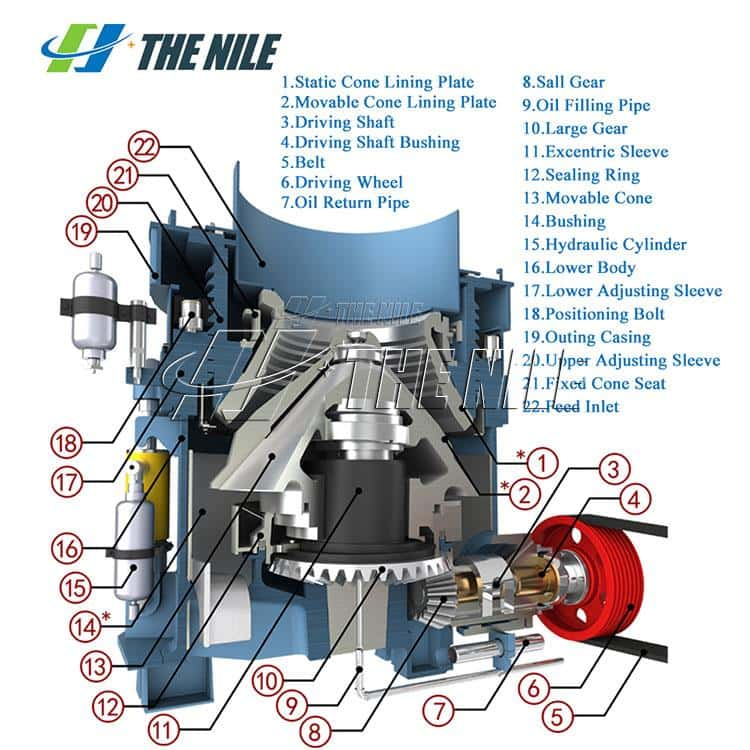

When the hydraulic cone crusher is working, the motor drives the eccentric bearing bushing, transmission shaft and a couple of cone gear wheel. The crushing cone axis is forced to swing by the eccentric bearing bushing, which makes the mantle sometimes close to the bowl liner, and sometimes far away from the bowl liner. The raw materials are pressed, impacted and finally crushed in the crushing chamber.

Technical parameters

Model | Type of cavity | Min output | Feed opening size | Capacity | Motor power | Moving cone diameter |

(mm) | (mm) | (t/h) | (kw) | (mm) | ||

HPY200 | C | 13 | 150 | 120-240 | 160 | 950 |

F | 6 | 76 | 55-180 | |||

HPY300 | C | 13 | 225 | 150-430 | 220 | 1160 |

F | 6 | 86 | 90-260 | |||

HPY400 | C | 13 | 290 | 190-610 | 315 | 1400 |

F | 6 | 100 | 108-320 | |||

HPY500 | C | 13 | 320 | 230-700 | 400 | 1500 |

F | 6 | 110 | 145-430 | |||

HPY800 | C | 13 | 350 | 325-1150 | 630 | 1800 |

F | 8 | 120 | 245-730 |